November 17, 2023

Kobe Steel, Ltd.

Kobe Steel, Ltd. announces that it has been awarded a contract to supply printed circuit heat exchanger (PCHE) units from JGC Corporation, which is a main contractor for a floating liquefied natural gas (FLNG) plant project in Malaysia.

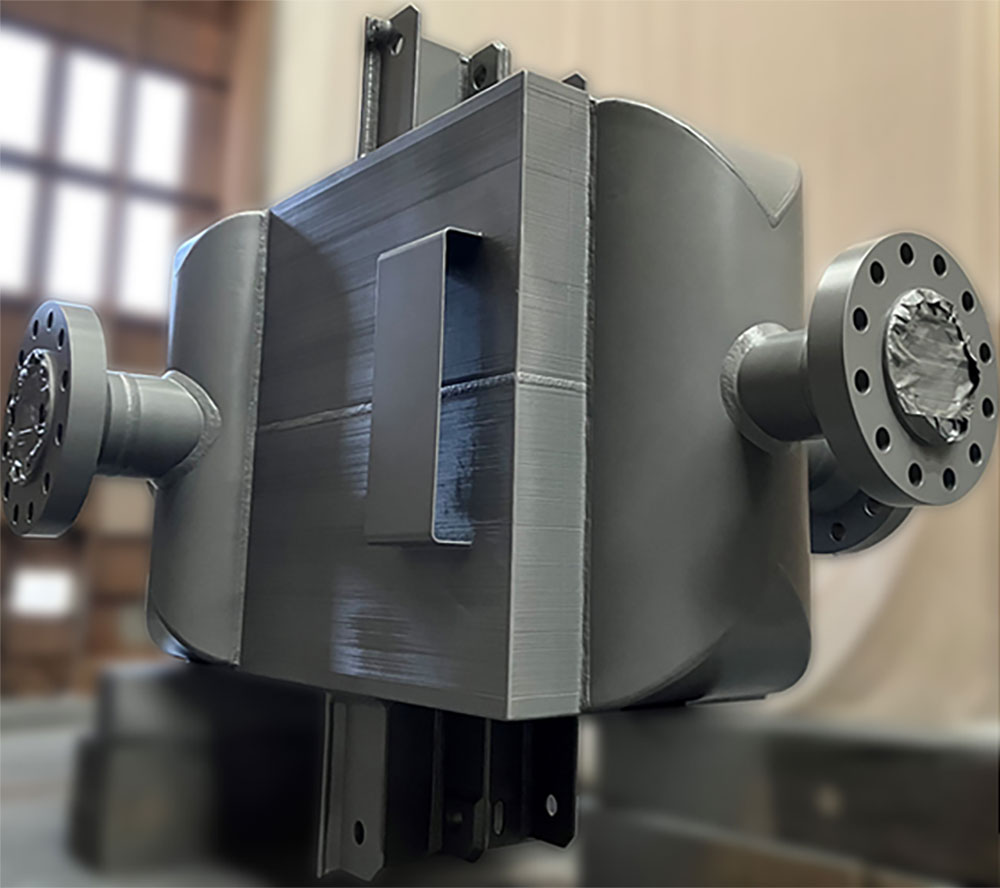

Kobe Steel commercialized PCHE in 2012 under the brand name “Diffusion-bonded Compact Heat Exchanger (DCHE)”, leveraging its expertise of over 50 years in the design and manufacture of heat exchangers. Compared with conventional heat exchangers with a shell and tube structure (double tube type), our PCHE is designed to have a wider heat transfer area (approx. 1,000 m2/m3), compactness (approx. 1/10 in size), and resistance to ultra-high pressure (100 MPa) by making laminated fine flow channels of 1-2 mm in width on stainless steel plate and joining them by diffusion bonding*. For these features, Kobe Steel already has a large global market share of heat exchangers for hydrogen filling stations, but this new order has been placed for PCHE units for use in a large-scale FLNG plant. We will further expand sales of PCHE for offshore platforms, vessels and floating facilities.

Our company will continue to provide solutions to the needs of society, by making the best use of the talents of our employees and our technologies.

* Diffusion bonding is a type of joining method like welding. In this method, materials are bonded together at an atomic level with heat and pressure at a high temperature. Diffusion bonding is suitable for joining fine flow channels and complicated three-dimensional structures because it can join materials without melting the base material unlike general welding.

printed circuit heat exchanger (PCHE)

(Note) The information on this web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.