February 18, 2016

Kobe Steel, Ltd. received the Tire Manufacturing Innovation of the Year award for its new tangential rotor called the 5THR in the Tire Technology International Awards for Innovation and Excellence 2016. The awards ceremony was held on February 17 at Tire Technology Expo, which is being held from February 16 to 18 in Hannover, Germany.

Rotors are used in mixers to mix rubber compounds for tire manufacturing. The 5THR rotor is noted for uniformly and efficiently mixing additives. In comparison to Kobe Steel’s conventional rotors, the 5THR offers an 8 percent improvement in quality and 43 percent higher productivity. Contributing to the reduction of CO2 emissions, the 5THR was highly evaluated for its mixing of silica-rich compounds used in making low-rolling resistance tires. Demand for this type of tire has been growing in recent years.

Tire Technology Expo is the world's most important tire manufacturing technology exhibition and conference. It is organized by magazine and events company UKIP Media & Events Ltd, which publishes Tire Technology International. This year’s Expo showcases technologies, materials and services for tire manufacturing from over 270 companies.

Low-rolling resistance tires are used mainly in passenger cars. In the future, the application of these tires is also anticipated to increase in trucks, buses and other commercial vehicles. The mixing ratio of silica in passenger car tires is also anticipated to increase in the future.

The 5THR rotor is compatible with Kobe Steel’s conventional rotors. One of its features is that the dimensions of the 5THR have been taken into consideration in order to replace existing rotors. As the use of the 5THR offers tire makers an effective method to respond to higher production for low-rolling resistance tires, Kobe Steel plans to expand its worldwide sales of the rotor in the coming years.

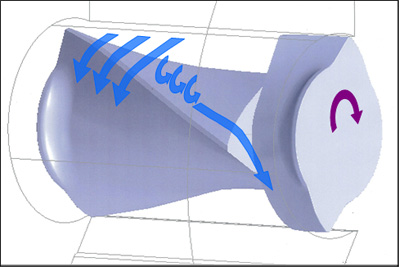

These rotors are used in tangential mixers. In a tangential mixer, the rotors do not mesh. Tangential mixers are smaller than intermeshing mixers. They are noted for their compact size and high productivity. On the other hand, tangential rotors offer lower contact area between the rotor and rubber compound and have lower cooling capacity than intermeshing rotors. While the 5THR is a tangential rotor, one of its features is its improved cooling capacity.

In addition to black carbon, low-rolling resistance tires contain silica. As silica is harder to disperse uniformly than carbon black, a large amount of energy is expended during compound mixing. In comparison to carbon black, silica mixing has a higher heat value. As rubber combusts at 200ºC, temperature control is difficult. If the temperature in the rubber mixer becomes too high, the rubber must be discharged, cooled and reloaded into the mixer.

In the 5THR, the shape of the rotor and a design to facilitate the flow of cooling water to the rotor improve the cooling capacity of the rubber compound during mixing. As a result, the heat generated from the energy necessary to disperse the silica can be suppressed during compounding. In comparison to Kobe Steel’s conventional rotors, the 5THR offers 43 percent higher productivity. With the more uniform dispersion of the silica particles, the 5THR achieves an 8 percent improvement in the performance of the mixed rubber required for low-rolling resistance tires.

The Kobe Steel Group manufactures and supplies tire and rubber machinery from four locations worldwide: Takasago Works in Japan; Kobelco Stewart Bolling, Inc. in the United States; L&T Kobelco Machinery Private Limited in India; and Yiyang Yishen Rubber Machinery Co., Ltd. in China. Regarded as the top maker of rubber mixers, Kobe Steel is aiming to take a 50% share of the world market.

Receiving the award on behalf of Kobe Steel: Hodaka Miura (right), Manager, Industrial Machinery Engineering Section, Machinery Business

Illustration of tangential rotor

(Note) The information on this web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.