Home > Press Releases > 2015 > Kobe Steel’s high-strength intermediate shafts for ships, first in the world to be adopted by international standard

Press Releases

The information on this Web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.

![]()

Kobe Steel’s high-strength intermediate shafts for ships, first in the world to be adopted by international standard

Kobe Steel’s high-strength intermediate shafts for ships, first in the world to be adopted by international standard

August 4, 2015

Kobe Steel, Ltd.’s high-strength intermediate shaft for ships has been adopted by the International Association of Classification Societies (IACS) under Unified Requirements (UR) for the first time in the world. Japan’s ship classification society, Nippon Kaiji Kyokai (also known as ClassNK), had previously qualified the steel forged product as a “special approved material.”

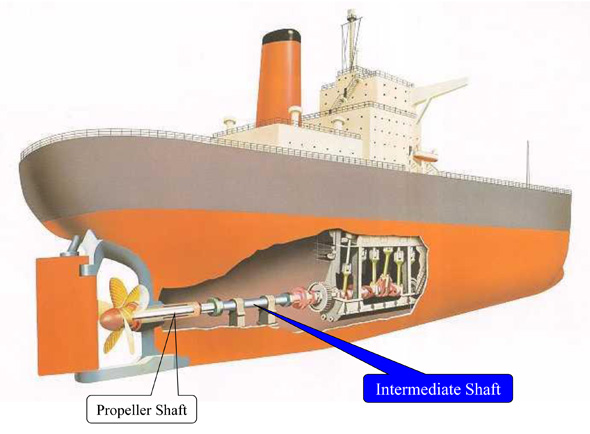

An intermediate shaft is an important component that transmits power from the engine to the propeller shaft. Recently, engines on large ships tend to adopt a low-speed, high-torque rotation design to achieve high output and high efficiency. To suppress torsional vibration in the intermediate shaft that occurs when the engine rotates at low speed, shafts of high strength are required.

High-strength material had reached a limit as under IACS UR, material design for intermediate shafts had a maximum tensile strength of TS800N/mm2.

With a background in production technology to make highly clean steel in an integrated manufacturing process from steelmaking to final product, Kobe Steel is able to produce high-strength steel up to TS950N/mm2. ClassNK gave recognition to Kobe Steel’s intermediate shaft as a special approved material and proposed to the IACS that the material be approved for UR. This led to the high-strength steel being adopted for UR up to TS950N/mm2.

Under IACS UR, it is now possible to design intermediate shafts of higher strength. Shafts of the same diameter will be better able to cope with large torsional vibrations. From the standpoint of the same torsional vibration stress, intermediate shafts of smaller diameters are also possible, saving on weight.

Kobe Steel’s casting and forging business supplies numerous ship components including built-up crankshafts, solid crankshafts, intermediate shafts and propeller shafts. These components are all inspected and assured under the highest and unique quality control system including the Automatic Ultrasonic Test (AUT) and quantitative digital evaluation of the contact area of crankshafts. Through these products, Kobe Steel is contributing to the advancement of the shipping and shipbuilding industries.