Home > Press Releases > 2013 > Kobe Steel begins marketing of new two-stage, inverter screw refrigeration compressor

Press Releases

The information on this Web site is presented "as is." Product availability, organization, and other content may differ from the time the information was originally posted. Changes may take place without notice.

![]()

Kobe Steel begins marketing of new two-stage, inverter screw refrigeration compressor

Kobe Steel begins marketing of new two-stage, inverter screw refrigeration compressor

Designed for use in food processing plants and warehouses

August 8, 2013

TOKYO, August 8, 2013 – Kobe Steel, Ltd. has developed a new refrigeration compressor to freeze and refrigerate food at food processing plants and warehouses. Kobe Steel has begun marketing the new compressor from August.

Called the iZN440TUA, the two-stage inverter ammonia screw compressor has the world's highest cooling rate with a coefficient of performance (COP) of 1.63 and the world's highest cooling capacity of about 400kW. By 2015, Kobe Steel anticipates sales of over 200 units from Japan and overseas markets, primarily Asia.

As food consumption increases amid the world's growing population, trade in food is also increasing. As an example, world trade in marine products reached approximately 20 million tons in 2000. In 2020, it is anticipated to grow to 33 million tons, according to a forecast by Japan's Fisheries Agency. For Japan, marine products make up a large proportion of food imports, especially from Asia.

Countries in Asia that produce and export food have many large-scale refrigeration plants for food processing and freezing, but food companies have been seeking refrigeration compressors with larger capacities and higher energy savings. To maintain quality during freezing, the refrigeration industry has also been cooling at lower temperatures, which is a specific feature of Kobe Steel's two-stage refrigeration compressors.

Until recently, Kobe Steel's maximum cooling capacity for its refrigeration compressors was in the 200kW range. Demand for compressors with high cooling capacities is anticipated to grow in emerging countries. To meet this need, Kobe Steel has recently developed and begun sales of the iZN440TUA, the two-stage, inverter screw refrigeration compressor with the world's highest cooling rate and the world's highest cooling capacity.

Kobe Steel is Japan's top manufacturer of refrigeration compressors with high market shares in its home country and East Asia. Kobe Steel is renowned for the high technical capabilities of its refrigeration compressors. It developed Japan's first ammonia screw refrigeration compressor package in 1963. In 2002, it succeeded in developing the world's first refrigeration compressor equipped with an inverter.

Kobe Steel's iZN Series of refrigeration compressors incorporates the latest, most advanced features among Kobe Steel's line-up of refrigeration compressors. The compression system, a core component in refrigeration compressors, makes use of Kobe Steel's outstanding screw technology accumulated over many years. Equipped with inverters, the iZN Series provides outstanding energy-saving operations. The iZN Series uses ammonia (NH3) as a natural refrigerant. This non-HCFC refrigerant does not damage the ozone layer and does not contribute to global warming.

The addition of the iZN440TUA to the iZN Series enables Kobe Steel to offer an array of refrigeration compressors ranging from 35kW to 400KW class. The IZN Series offers a full range of models to meet market needs and growing future demand.

Notes on Terms

![]()

Two-stage compression refers to the number of cylinder strokes needed to compress the refrigerant. Two-stage compression is generally more efficient than single-stage compression.

An inverter controls the operating speed of a compressor. In comparison to single-speed compressors, inverter compressors can adjust their operating speed depending on the operating load. This reduces energy consumption.

The new two-stage, inverter screw refrigeration compressor has the world's highest cooling rate and the highest cooling capacity.

Coefficient of Performance (COP) indicates the performance of heating and cooling equipment. COP is the cooling capacity (kW) divided by electricity consumption (kW). The higher the number, the more efficiency the equipment is.

A figure of COP 1.63 means that 1.63 times the heat energy is moved for every watt of electricity consumed. (The calculation conditions are a condensing temperature of 40 degrees C and a suction pressure saturation temperature of –40 degrees C.)

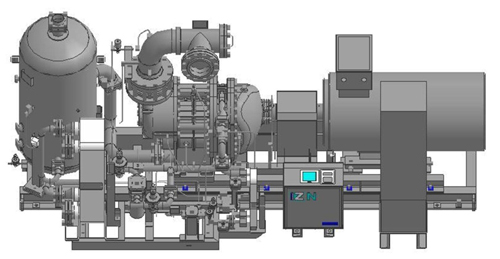

Conceptual drawing of iZN440TUA